Optimising Industrial Temperature Control with Indirect Evaporative Cooling

- Australia, Europe, Asia, Africa, Americas

- Commercial

- Sustainability, Cooling

Cooling Industrial and warehouse facilities

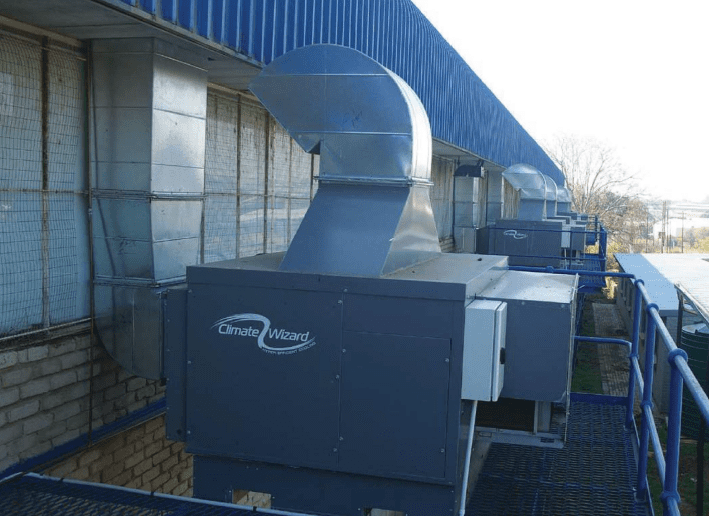

In the pursuit of energy efficiency and enhanced operational performance, industrial and warehouse facilities are increasingly looking at innovative temperature control solutions to lower operational costs. The Climate Wizard’s Indirect Evaporative Cooling (IDEC) technology, also known and referred to as M-Cycle Indirect Evaporative Cooling, is ideal for delivering adequate temperature control and optimal air quality in warehouses and factories. This innovative approach offers a plethora of benefits, including reduced carbon emissions, reliability, and substantial energy savings of up to 80% lower when compared to refrigerated systems performing the same duty.

The Benefits of Indirect Evaporative Cooling

Enhanced Energy Efficiency

The energy efficiency of IDEC systems can further be enhanced by coupling them with Air Handling Units (AHU). This integration can lead to further energy reduction, either by pre-cooling the AHU or boosting the efficiency of direct expansion (DX) or variable refrigerant flow (VRF) systems in supplementary applications. Energy saving is essential not only for reducing running costs but also supporting locations where power availability is an issue, or in industrial plants that need to reduce peak time energy consumption.

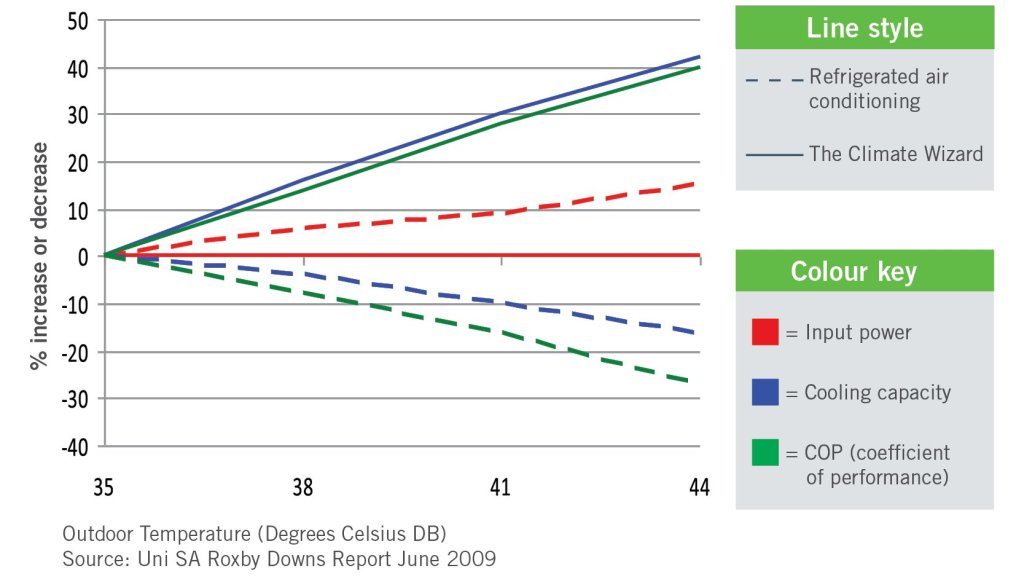

It is important to also note that all indirect evaporative coolers’ performance increases as temperature rises, in direct contrast to conventional air conditioning system that consume much more power to maintain the same levels when temperature increase. The chart below illustrates this.

The Climate Wizard vs refrigerated cooling capacity and COP as temperature rises

Low Carbon Emissions

IDEC systems, like the Climate Wizard, are designed to be highly energy-efficient, utilising natural adiabatic cooling processes to cool air without relying heavily on traditional refrigerants or compressors or adding any additional humidity to the working environment. This is crucial for production environments where added moisture can negatively affect product manufacturing and storage. The result is significantly lower carbon emissions compared to conventional air conditioning systems. By reducing the reliance on energy-intensive cooling methods, facilities can minimise their environmental footprint and contribute to global sustainability efforts.

Environmentally Friendly

The environmental benefits of IDEC extend beyond low emissions. By utilizing water, R-718, a renewable resource for cooling, IDEC reduces reliance on harmful chemicals found in traditional direct expansion (DX) or variable refrigerant flow (VRF) HVAC systems.

Refrigerants can be extremely harmful to the environment if released, damaging the ozone layer and contributing to climate change and impacting human health.

For example, in Australia:

- Improper handling and disposal of refrigerants contributes to emissions worth 2 million cars on the road in Australia each year.

- With the energy they consume, the 60 million systems across the country that use hydrofluorocarbons (HFCs) are responsible for 12% of Australia’s total emissions.1

This makes IDEC a sustainable choice for businesses looking to reduce their environmental impact, with the system utilising water to cool.

Low Maintenance and Ongoing Savings

IDEC systems are reliable, with low maintenance requirements. The Climate Wizard incorporates advanced materials such as powder coated marine grade aluminium and stainless steel as well as advance components from Schneider Electric that are designed for durability. Additionally, the significant reduction in electrical consumption translates to ongoing savings in energy costs. This financial benefit is twofold: lower operational expenses and a reduced need for expensive cooling infrastructure upgrades.

Comfortable, Healthy Fresh Air – Improved Indoor Air Quality

One of the standout features of indirect evaporative cooling is its ability to deliver fresh, filtered air into the workspace. Unlike traditional systems that recirculate stale indoor air, IDEC systems introduce 100% outside air, which is cooled indirectly. This process not only maintains a comfortable temperature but also ensures a constant supply of fresh, healthy air, enhancing indoor air quality and creating a more pleasant environment for employees.

Learn More about IAQImproved Workplace Environment

The advantages of IDEC are not just technical and financial; they also extend to employee well-being. A cooler, well-ventilated workspace can lead to happier, more productive staff. With improved air quality and consistent temperatures, employees are less likely to suffer from heat-related illnesses or exposure to volatile organic compounds (VOC), leading to fewer sick days and better overall focus and concentration. This creates a more efficient and motivated workforce, ultimately contributing to higher productivity and profitability.

To wrap up

Implementing indirect evaporative cooling technology like the Climate Wizard as a dedicated outdoor air system (DOAS) in an industrial or warehouse setting presents a compelling case for businesses aiming to optimise temperature control.

The benefits:

- Low carbon emissions

- Improved air quality

- Environmental friendliness

- Low maintenance

- Significant energy savings

- Better health and productivity of staff

Industrial and Warehousing HVAC Case Studies

Alpha Pharm Distribution Centre – Pretoria South Africa

The Alpha Pharm facility in Pretoria operates 24/7 and is approximately 4,500m2. It has been in operation since 1992 and distributes anything from 70,000 to 135,000 single items per day, with approx. 100 people on the floor and 40 people after hours.

Alpha Pharm replaced its ageing single-stage evaporative cooling system with a more suitable (and beneficial) Climate Wizard indirect evaporative cooling solution.

Learn More

Tri Tool Inc – California United States

A unique challenge – to provide cooling to a large shop where airborne fumes are generated as part of the machining process.

The solution – A single CW-160 that delivers 11,800 l/s (25,000 cfm) into the machine shop via ducts arranged internally, across one wall of the building. Exit paths for the existing air were installed on the opposite side of the building. This allows the fresh cool air to purge away the contaminated air.

Learn more

The solution – A single CW-160 that delivers 11,800 l/s (25,000 cfm) into the machine shop via ducts arranged internally, across one wall of the building. Exit paths for the existing air were installed on the opposite side of the building. This allows the fresh cool air to purge away the contaminated air.