HVAC Case Study

DeWALT Industrial Tools

Improved factory ventilation and Indoor Air Quality (IAQ) in the industrial plant after installing Breezair evaporative cooling for ventilation

Project Background: Factory ventilation improvement

DeWalt Industrial Tools is a subsidiary of Stanley Black & Decker group, world global leader in manufacturing of professional power tools. In the Perugia manufacturing plant, the company manufactures tools for cutting wood and demolition hammers, their two main product families.

Today the Perugia factory has 250 employees. The building is located in an area of about 14,000 square metres, of which 9,000 are dedicated to production.

Over the last ten years, due to climate change and the increase in latent heat, they have experienced Summer temperatures higher than 35°C. This has resulted in very difficult working conditions and an urgent need for improving the factory ventilation.

The company’s goal was to re-establish a comfortable indoor climate , lowering temperatures and ensuring proper factory ventilation with the correct number of air changes and outside air.

The company has always been committed to eco-friendly operations with a low environmental impact, so the research also had to meet these requirements.

Project Solution

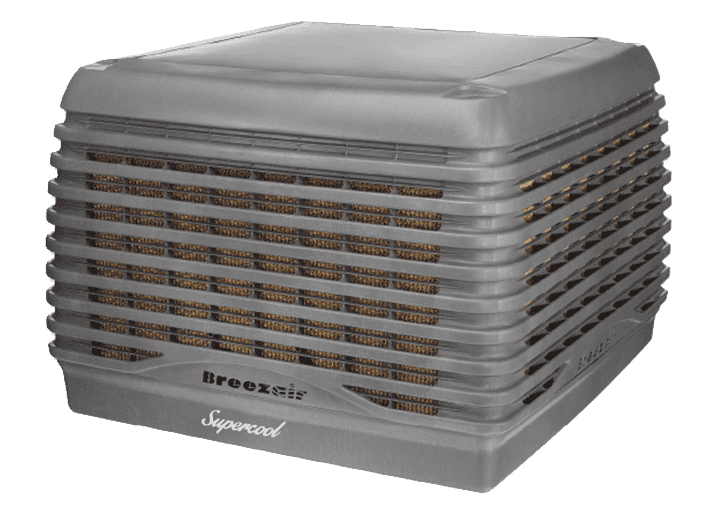

The EHS & Facility Manager made contact with Italkero, who presented Breezair evaporative coolers as the best solution for their heat issue.

First of all, Breezair can efficiently cool vast building of similar sizes with reduced running costs. Secondly, only using water and little electricity to run, it is one of the most environmentally friendly cooling solutions for factory ventilation available in the market.

Italkero’s professionalism, combined with Breezair’s reliability and premium quality, convinced the Management to opt for this great sustainable solution.

Project Installation

Installation was conducted in three phases, from 2019 to 2021, resulting in:

• 27 Breezair TBS580 units installed on the roof with vertical supply ductworks

• 17 Breezair TBS580 units mounted off the external walls with horizontal ducts

The units are controlled using MagIQtouch wall controllers, which allow easy system operation control and system group management.

Project Results: a great factory ventilation improvement project

The initial goals were fully met, with great satisfaction of both employees and management.

Not only have they improved working conditions by lowering temperatures and increasing Indoor Air Quality, but they also met the energy efficiency and sustainability objectives the Management had originally set.

In the summer, indoor temperatures in the production plant can be maintained at a constant 27°C.

DeWALT are considering the installation of more cooling units in the remaining 4,000 square metres of the industrial plant, which would ensure total coverage. At the same time, they are also thinking of installing two indirect evaporative cooling units in the canteen. Subsidiary of Stanley Black and Decker Group, DeWALT production plant in Perugia is no longer experiencing excessive Summer temperatures and machines tripping because of the heat.

Download DeWALT Industrial Tools Case Study PDF

Are you curious to see how Breezair evaporative cooling works? Watch this video!

HVAC Case Study Overview

Industry

Industrial / Manufacturing

Country

Italy

Region

Umbria

Technology

Direct Evaporative Cooling

Application

Stand-alone Cooling

Brand

Breezair