HVAC Case Study

Manufactura Turnu Magurele

Providing fresh air for hundreds of production workers, with reduced running costs

The issue

Manufactura Turnu Magurele is a modern tailoring factory. They produce clothing for famous designers like Armani, Dolce Gabbana, Patrizia Pepe, Valentino, Pinko etc…

The factory floor is 600 m² with over 500 sewing machines organised in 18 production lines. Specialised in knitting, more than 400 workers produce around 4,000-5,000 clothing pieces every day. The production area was previously equipped with a heating system, but with no system to cool the air during Summer. This had become a significant problem, especially because of the huge glass windows in the area (with a consequent greenhouse effect, multiplying the heat).

The textile factory air conditioning solution

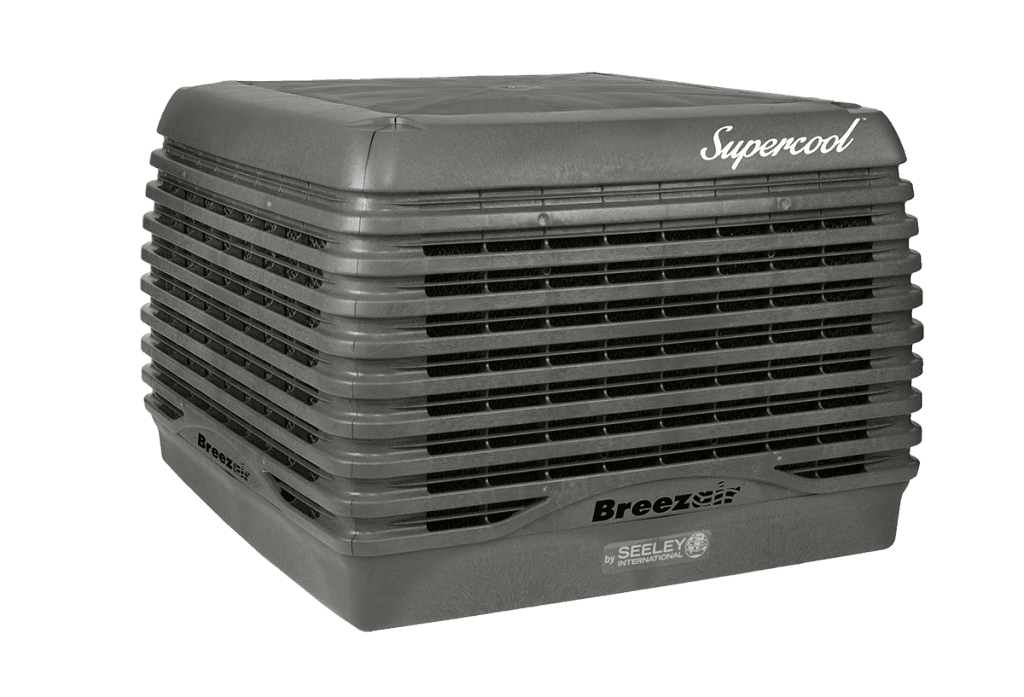

The management contacted Westair to solve the heat issue. The official distributor for Romania suggested to install 4 Breezair evaporative coolers as textile factory cooling system.

The company installed the coolers on the roof of the factory, with a textile ducting system to conduct the air in the area.

“I’m happy with the chosen textile factory air conditioning system.” says the owner of the Manufactura, Mr Nazzareno Mariangeli. “It does not only provide fresh air, so necessary for the hundreds of production workers, but most importantly runs at a much lower cost. In an old warehouse with similar dimensions we installed a chiller and fan coils running on very hot summer days only. However, the energy consumption was around 50 Kw/hour. In the new production hall, Breezair uses 5 Kw/hour only! It’s unbelievable!”

“The energetic efficiency, notwithstanding the ridiculously low costs of running, made Breezair a champion in the fight against the heat, especially for industrial spaces” says Sorin Lumina, General Director of West Air Grup, the exclusive importer of Breezair in Romania.

Why Breezair?

Breezair is the perfect solution for textile factory air conditioning.

- 100% fresh outside air

- Improved Indoor Air Quality

- Low running costs

- Easy installation and maintenance

HVAC Case Study Overview

Industry

Industrial / Manufacturing

Country

Romania

Region

Muntenia

Technology

Direct Evaporative Cooling

Application

Stand-alone Cooling

Brand

Breezair

Products Used

Breezair Supercool TBA 550 Evaporative Cooler