HVAC Case Study

Aryzta Bakery

Global Food Business Benefits From Significant Energy Savings

Food manufacturing presents a unique set of challenges, particularly around critical control points to ensure delivery of safe food products to consumers and customers alike. Part of this process relies heavily on temperature and climate control within the manufacturing process.

ARYZTA is an international food business and a global supplier to the foodservice, retail and QSR sectors.

Offering an impressive range of products and capabilities including a variety of breads and sweet and savoury foods.

Operating 54 bakeries across Europe, North America, South America, Asia, Australia and New Zealand, the group boasts strong brands with a leadership position in frozen B2B bakery.

Project Requirements

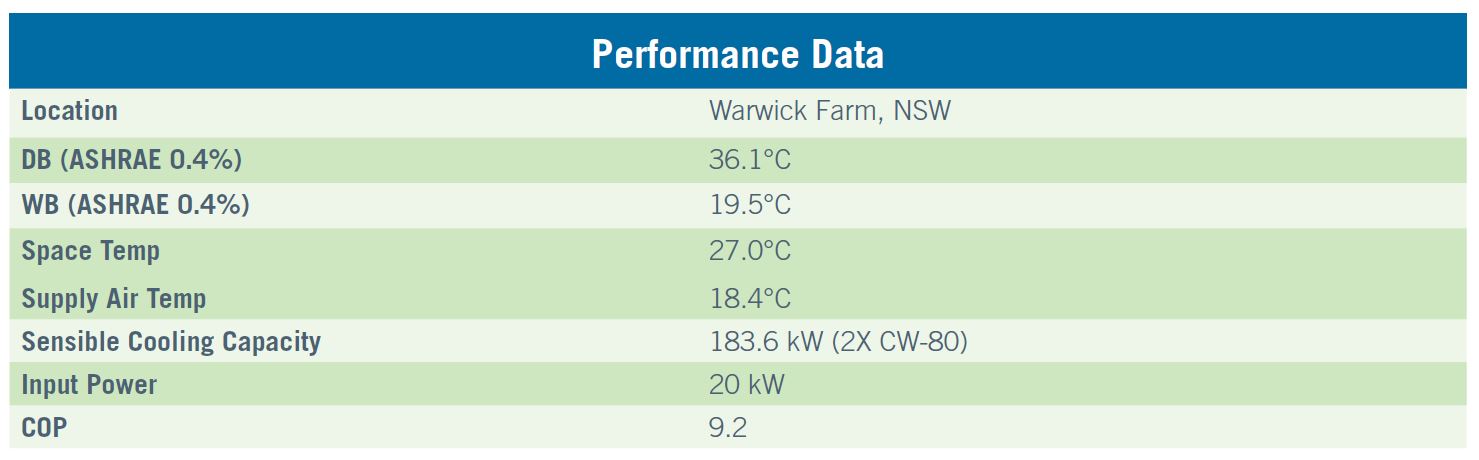

The facility in Warwick Farm hosts a proofing and oven area that produces over 60,000 buns per hour. Around 10 large bakery machines and other equipment, emitting temperatures ranging from 35°C to 60°C, all creating a significantly warm working environment for its factory workers, particularly in peak Summer periods.

The existing AHUs (air handling units) were approaching the end of their life cycle and the business set out with the goal to replace them with energy efficient units that operate over a wide temperature range and deliver 100% outside air.

- The solution needed to consist of energy efficient equipment with a lower operational cost

- Maintain a consistent area temperature of 27°C in the factory at all times, across a 1,960m2 floor area, providing safe and comfortable working conditions for employees

- The bakery had to remain open and operational during the installation which presented a challenge

The Solution

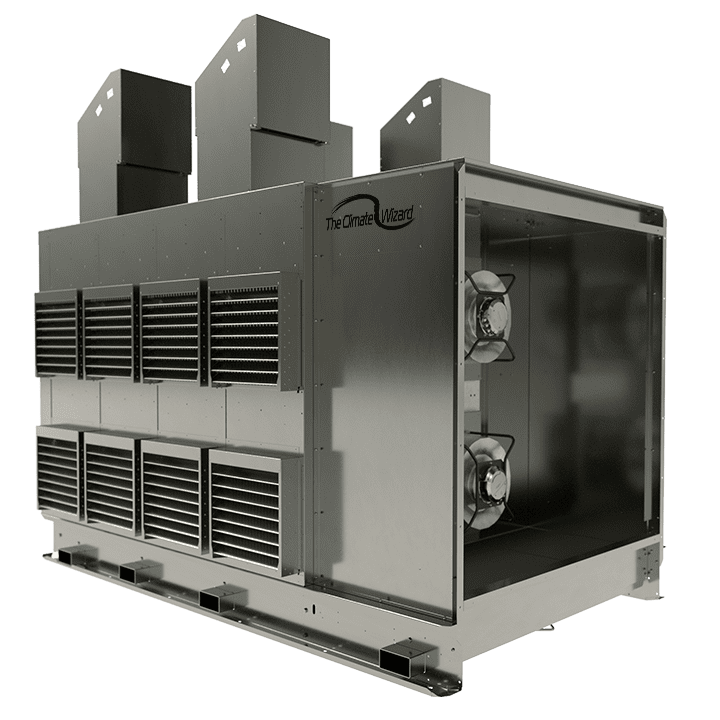

With these key requirements in mind, Climate Wizard was quickly determined as the perfect solution. 2 x Climate Wizard CW-80 units where selected, together with a well-designed duct work system distributing pre-cooled air to the area.

The units were installed on prefabricated roof platforms and ducted into the bakery factory area, using double deflection grilles to diffuse the air. The final solution provides a total stand-alone cooling capacity of 183.7 kW and a total input power of 20.0 kW, which is 68% less input power use than a traditional refrigerated system.

The Results

The client is extremely happy with the final result and the cooler air temperatures and comfort levels that the CW units are delivering. The solution delivers peak input power savings of 49.2 kW and annual energy savings of 175,700 kWh.

Download Case Study

HVAC Case Study Overview

Industry

Retail & Supermarket

Country

Australia

Region

New South Wales

Technology

Indirect Evaporative Cooling

Application

Stand-alone Cooling

Brand

Climate Wizard