HVAC Case Study

Las Cervezas Modelo Brewery

Global Beverage Company Benefits From Hyper-Efficient Cooling Solution

Constellation Brands Inc. is a Fortune 500 company and an American producer and marketer of beer, wine and spirits. The company recently invested $900 million to expand the production capacity of its production facility in Ciudad Obregón, Sonora, Mexico.

The investment allows for further expansion to the production capacity of the facility by approximately 5 million hectolitres over the next four years and will create up to 450 new jobs.

Project Requirements

The project required a cooling solution to be installed within the brewery engine room to provide optimal internal climate conditions to support 4 ammonia chiller compressors (over 1 MW) operating within the factory.

- Provide hyper-efficient process cooling to a 1,400 kW (400 RT) load, ensuring mission critical system warranties are never voided by exceeding their required thermal operating envelope.

- Determine how to evenly deliver air cooling to a massive industrial load in a mechanical room dominated by extensive piping runs that do not allow room to pass large air ducts.

- Do so without adding humidity that would ultimately degrade plant reliability.

- Deliver and maintain optimal conditions for workers within the plant, including fresh air ventilation.

Project Deliverables

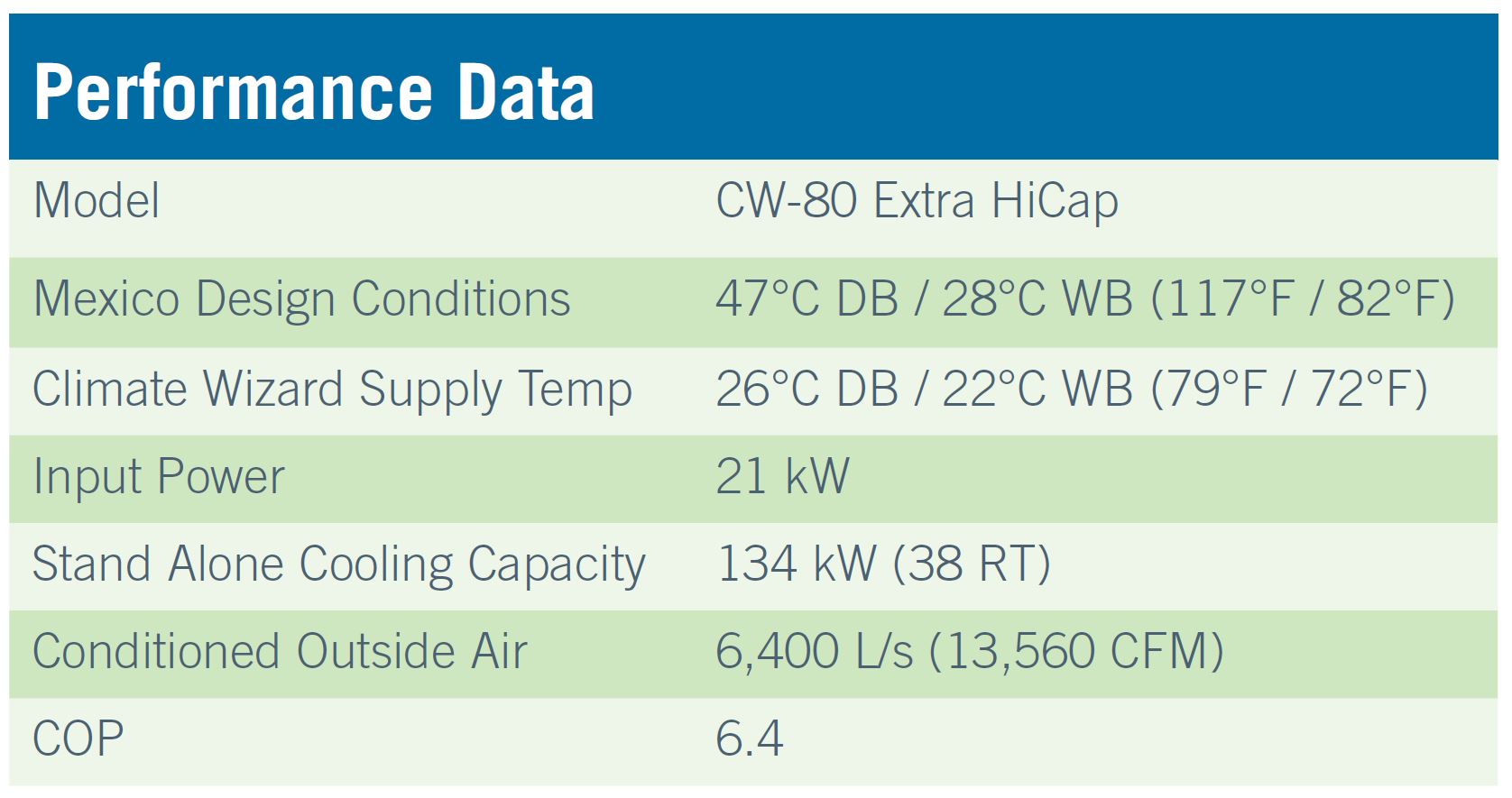

Stage 1 of the Project required a cooling solution for the engine room area totaling 2,787 m2 (30,000 ft2). A total of 12 Climate Wizard CW-80 units with high capacity motors were specified into the system design, delivering a total of 1,182 kW of cooling (336 RT) which are distributed in two zones.

The project’s operational Zone A has 6 x CW-80 installed and 8 exhaust blowers. Zone A consists of the compressors, motors and cooling towers.

The project’s Zone B has 6 x CW-80 installed to handle miscellaneous loads such as the Administration offices and IT room.

The operating configuration of the Climate Wizard units are designed to run in COOL mode as soon as the outside temperature is above 43.3°C (110 °F) and to operate in ventilation mode as soon as the outside temperature reaches 35°C (95 °F). A comparative Direct Expansion (DX) system (refrigerated air conditioning) to be considered for this project would have involved installing 1,480 kW (420 RT) of air conditioning, which meant a much higher operating, energy and maintenance cost, as well as a larger up front capital cost, without considering a 100% fresh air operation.

The project has a 100 HP extraction system installed and the positive pressure and control systems allow limiting the amount of ammonia particles suspended in the environment.

Results

Seeley projects a peak demand reduction of 350 kW (65%) and annual operating cost-savings of over 75%, exceeding 1,428,000 kWh or US $100,000 (AUD $125,000). 37,755 L/s (80,000 cfm) of cooled 100% outdoor air to maintain operating environment below 43.3°C (110 °F).

Seeley was able to offer an extra-high capacity fan option providing over 3” (75 mm) water gauge external static to allow for downsizing of the supply ducts so they could fit through the literal bottleneck and still deliver very attractive energy savings.

Given the success of the Stage 1 cooling installation and the performance of Climate Wizard for this application, Stage 2 of the project includes the installation of a further 12 x CW- 80 units.

HVAC Case Study Overview

Industry

Agriculture / Plant Propagation

Country

Mexico

Region

Ciudad Obregón

Technology

Indirect Evaporative Cooling

Application

Stand-alone Cooling

Brand

Climate Wizard