Plastic industry cooling with Seeley International solutions

Evaporative cooling is a great option when high heat levels or chemical usage negatively impact Indoor Air Quality.

Plastic industry cooling

Seeley International offers advanced cooling units specifically designed for the plastic industry, providing an effective and sustainable way to control temperature and humidity in manufacturing and storage areas. These systems deliver precise management of these factors, ensuring the quality of plastic products while also minimizing energy consumption and reducing environmental impact. Plastic manufacturing often involves the use of chemical substances that can release toxic fumes, leading to poor indoor air quality (IAQ) and wasting valuable air.

By installing a fixed cooling solution in your facility, you create a controlled environment that stabilizes the production process, preserves product integrity, and improves internal IAQ. With an evaporative cooling system that provides 100% fresh air, you can eliminate harmful chemicals from the air, enhancing the health and comfort of your workspace. Not only does this system improve overall efficiency, but it also results in long-term cost savings.

With a focus on energy efficiency and sustainability, you can lower energy bills, enhance product quality, and decrease your environmental footprint while ensuring a safer and cleaner working environment.

Discover how this innovative cooling technology can optimize your production processes, elevate product quality, and help you move toward a more sustainable business model.

Energy efficient

Cost saving A/C solution

Ideal for plastic processing environments

Improved Indoor Air Quality (IAQ)

Sustainable solution

High scalability

Benefits for Plastic industry Cooling

Better Air Quality: The system consistently provides fresh air and controls humidity levels, maintaining ideal conditions for plastic manufacturing and storage. It helps eliminate odors, airborne pollutants, and prevents the buildup of chemical substances. The continuous airflow enhances Indoor Air Quality and creates a better work environment for employees.

Energy Efficiency: Reduces energy consumption and utility costs compared to traditional cooling systems, making it a cost-effective choice for plastic manufacturers.

Cost-Effective: Requires minimal maintenance and operates at a low cost, ensuring optimal indoor air quality (IAQ) while effectively managing chemical substances. This makes it a cost-effective solution for maintaining ideal conditions in your facility with reduced upkeep.

Eco-Friendly: Utilizes water and natural airflow to cool the space, reducing environmental impact and supporting your business’s sustainability goals.

Enhanced Product Quality: By regulating temperature and humidity consistently, the system helps maintain the quality of your plastic products, enhances the production process, and ensures a comfortable and productive environment for your staff.

Seeley International's top-tier evaporative cooling solutions are ideal for cooling in plastic processing industries.

Harness the power of Evaporative cooling

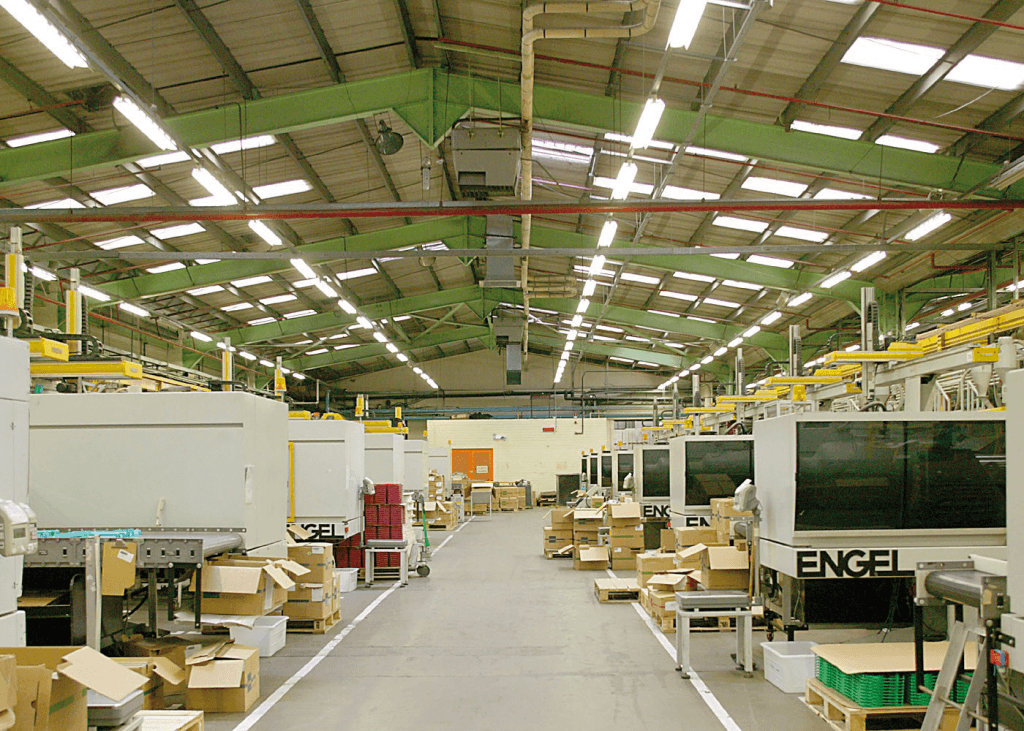

Hasbro Ireland installed Breezair Evaporative Cooling in its 23,000-square-meter factory to address high temperatures in the plastic injection moulding workshop. The Breezair coolers reduced temperatures from 30°C to a comfortable 23°C, significantly improving working conditions and boosting productivity. Before the installation, poor thermal conditions in the workshop, worsened by 36 moulding machines, led to worker fatigue and low morale. The success of the system led to the installation of additional coolers in other high-temperature areas of the factory. The result has been a dramatic reduction in complaints, improved morale, and a more comfortable, productive work environment.

Evaporative Cooling Applications

Evaporative air conditioning has a wide range of cooling applications

Evaporative cooling is a highly effective solution for the plastic industry, where controlling temperature and humidity is crucial to maintaining product quality and improving production efficiency. This system provides 100% fresh, filtered air, enhancing ventilation and lowering CO2 and VOC levels. By regulating both temperature and humidity, it creates an ideal environment for plastic manufacturing and storage, preserving product integrity while ensuring a comfortable and productive atmosphere for employees.

Click on each application to discover the unique benefits for each scenario!

The evaporative air conditioning system offers a budget-friendly and energy-efficient cooling solution, ideal for plastic manufacturing facilities, warehouses, and large production areas. It provides effective cooling while consuming up to 80% less energy compared to conventional refrigerated systems, making it especially suitable for environments where doors are often opened and closed.

Evaporative cooling is perfect for industries such as plastics, pharmaceuticals, textiles, and more, offering significant improvements in Indoor Air Quality (IAQ). It ensures a continuous flow of fresh air, utilizes natural filtration through cooling pads, and helps reduce pollutants, dust, and odors. By adding moisture to the air, it also regulates humidity levels, preventing dryness and minimizing static electricity. Unlike traditional HVAC systems, evaporative cooling doesn’t recycle air, which helps prevent the accumulation of chemical substances in the air. This leads to a healthier working environment, improving comfort, reducing respiratory irritation, and boosting worker productivity in plastic manufacturing spaces.

Contact an HVAC Sales Engineer

Speak to one of our HVAC experts about your project requirements...

Industrial air conditioning unit Frequently Asked Questions

- Evaporative air conditioners (coolers) are excellent for health

- They supply 100% fresh, filtered air into your building that is not recirculated, improving Indoor Air Quality (IAQ) of the space, supporting customer and staff well-being

- They remove unhealthy pollution from your indoor environment

- They provide basic moisture that the human body needs

- They remove static electricity; they can assist in reducing the effects of illnesses such as asthma.

A high inlet water temperature does not have a marked effect on the supply temperature of Seeley International’s evaporative air conditioners.

Yes. Outdoor areas have no walls to contain the cool air. These spaces would be impossible to cool using refrigerated air conditioning because this relies on recirculating and reusing air from a sealed area. Evaporative air conditioners (coolers) can easily supply a flow of fresh and cool air to open and semi open areas since the air is exhausted naturally.

In most cases evaporative air conditioners (coolers) marginally increase humidity, keeping in mind that temperature has also dropped significantly. It is the combination of temperature, humidity and airflow that creates human comfort and evaporative air conditioners are used widely around the world because they can create comfortable conditions. For example, 80% humidity and 30°C (86°F) is very uncomfortable, but 80% humidity and 16°C (61°F) is very comfortable. Comfort is also improved by increasing air velocity in hot conditions and evaporative air conditioners create sufficient air movement to minimise the effects of humidity.

Air inside the building collects heat, moisture and impurities and must be exhausted. The evaporative air conditioner (cooler) provides 100% outside air which must be relieved from the building. If the building is sealed, the effectiveness of the cooler(s) will be reduced. Mechanical extraction or even just leaving some doors or windows open helps remove unhealthy air from the indoor environment by supplying 100% fresh, filtered air. For this reason, evaporative air conditioners (coolers) are much healthier than refrigerated air conditioning.

View more Frequently Asked Questions here.

Plastic industry cooling with evaporative cooling system

From small production facilities to large manufacturing plants, Seeley International evaporative coolers are designed to meet the diverse cooling needs of specific industries, such as the plastic and textile industries, where chemical substances are processed and handled.