HVAC Case Study

AJ Baker

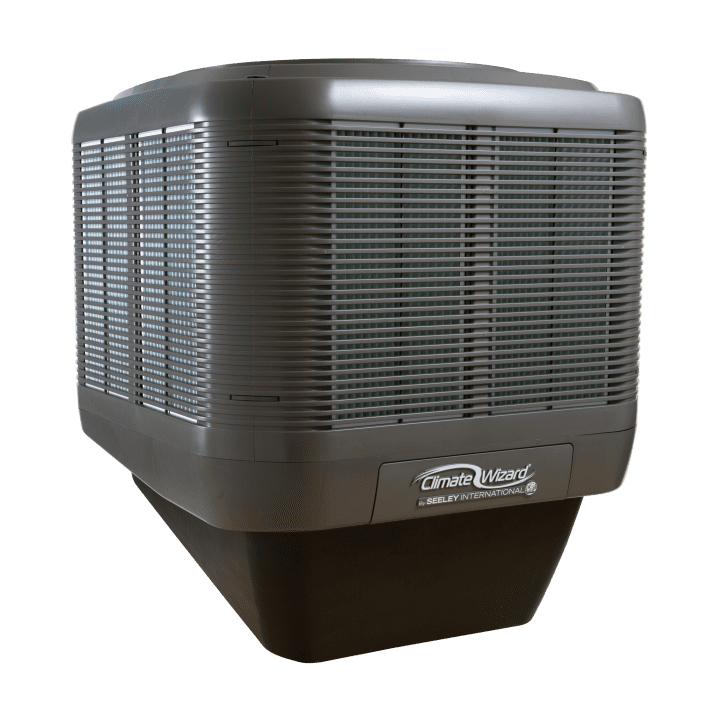

Climate Wizard CW-6S Units Deliver Energy-Efficient Cooling for Manufacturing Facility

AJ Baker required an energy-efficient air conditioning solution for their 2,000 square metre manufacturing facility in South Australia. Choosing Climate Wizard CW-6S allowed them to provide a cool and comfortable environment for their workers, improving productivity and staff well being. AJ Baker are also benefiting increased energy efficiency and cost savings.

AJ Baker & Sons: A Leader in Refrigeration Solutions

AJ Baker & Sons specialises in the design, installation, servicing, and maintenance of various commercial refrigeration cabinets, ice machines, and air conditioning systems. With an extensive portfolio catering to supermarkets, fast food chains, the hotel industry, and small to medium-sized commercial projects, AJ Baker has a proud history and continues to evolve to maintain a strong presence in the Australian refrigeration industry.

The Challenge: Cooling a Large Manufacturing Facility

AJ Baker’s South Australian manufacturing facility spans an impressive 2,000 square metres, making it vital to address the high ambient temperatures that can arise during the South Australian summer. Ensuring a comfortable working environment for their employees was a top priority for the company, as it directly impacts productivity and staff well-being. In addition, AJ Baker sought a solution that would provide efficient cooling while minimising energy consumption and operating costs.

The Solution: Climate Wizard CW-6S Units

After careful consideration, AJ Baker selected the Climate Wizard CW-6S units as the optimal solution for cooling their manufacturing facility. These hyper-efficient indirect evaporative air conditioning units employ innovative technology to deliver exceptional performance and energy efficiency. By harnessing the power of evaporative cooling, the Climate Wizard units utilise an indirect heat exchange core and direct evaporative cooling to provide effective cooling while significantly reducing energy consumption.

Key Benefits and Results

The installation of the Climate Wizard CW-6S units at AJ Baker’s manufacturing facility has yielded several significant benefits and positive outcomes:

- Improved Worker Comfort: The Climate Wizard units efficiently produce cooling, creating a comfortable environment that allows employees to work productively and comfortably throughout the year.

- Enhanced Energy Efficiency: By leveraging indirect evaporative cooling technology, the Climate Wizard units minimise energy consumption, resulting in reduced operating costs and increased energy efficiency for AJ Baker.

- Fresh Air Ventilation: The units provide 100% cool, outside air to the building, ensuring high levels of fresh air ventilation. This feature plays a crucial role in removing fumes and volatile organic compounds (VOCs) generated during the manufacturing process, contributing to a healthier and safer work environment.

Conclusion:

The successful implementation of Seeley International’s Climate Wizard CW-6S units at AJ Baker’s manufacturing facility in South Australia highlights the positive impact of energy-efficient air conditioning solutions on worker comfort, productivity, and cost savings. By prioritising employee well-being and leveraging innovative technology, AJ Baker has set a commendable example in the refrigeration industry.

HVAC Case Study Overview

Industry

Agriculture / Plant Propagation

Country

Australia

Region

South Australia

Technology

Direct Evaporative Cooling

Application

Add-on Cooling

Brand

Climate Wizard